We have expertise in a wide range of applications, including pickling and regeneration plants, vessels, flue gas lines and reactors, autoclaves, and absorption towers. Both theoretically and practically. This is something we consider when selecting the acid proofing lining system for the process at hand, as well as when providing you with specialized advice.

As a specialist, we naturally provide highly unique solutions. To that aim, we have remarkable and unique technological know-how, such as for high temperatures, autoclaves, and pressure vessels.

We are constantly developing and improving our product offering. This enables us to service our clients’ most sophisticated and current plant technology. We blend sealing layers, mortar, and carbon-based materials to develop custom solutions for your project.

We may work out innovative solutions with our development departments at any moment, in addition to getting access to our vast choice of materials.

Types of Acid Proof Lining

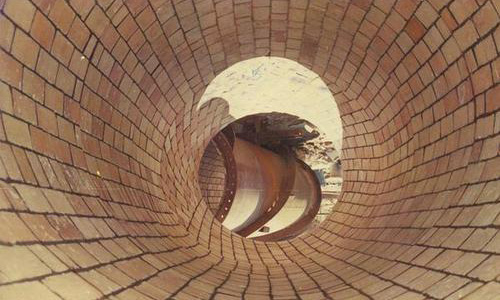

Brick Lining Tile

It is a high-quality acid proof lining system that is used to prevent corrosion in large chemical plants. Bricks of various sizes are added and joined with acid proof concrete. The cement employed varies according to the chemical condition, temperature & specified limitations.

Acid Proof Tile Lining

It is commonly used in drainage systems, ceilings, foundations, vessel roofs, and so on. It is additionally added and joined with other acid proofing lining materials. Acid proof tile lining comes in a variety of sizes and thicknesses.

Mandana Stone Lining

Mandana Stone Lining is commonly used on chemical processing floors, where it is added and joined with acid proofing concrete.

Epoxy Lining

It is a solvent, transparent epoxy acid proof lining system that is implemented in chemical storage facilities, pits, floors, and ETP tanks, among other places. Lined in thicknesses ranging from 3mm to 5mm and higher. It is highly suggested for projects involving aircraft, breweries, automobiles, sugar, dairy, and textiles.

Coltar Epoxy Lining

This is a Cottar bade Epoxy acid proof tile lining system that is employed in areas where mild acids, alkalies, or wastewater with a low PH value are present. It is particularly resistant to ETP, wasted water storage chambers, drains, and so on.

Carbon Brick Lining

It is highly suggested in areas where fluoride, hydrofluoric acid, and extremely powerful alkalies are used. Carbon Bricks come in a variety of sizes and are added and joined with premium quality carbon-filled cement.

F. R. P. Lining

It is a Polyester Resine base acid proofing lining system that is beneficial in areas where certain acids and alkalies are present. Best for chemical and reaction tanks, storage tank foundations, and structures, among other factors. It is manufactured in thicknesses ranging from 4mm to 6mm and beyond, according to the client’s needs.

Top 3 Best Acid Proofing Lining Materials

Acid Proof Bricks

Acid proof bricks and acid proof tile lining are commonly used in practically every corner of the world. As acid proof bricks manufacturers point out, there are several advantages to adopting acid proof brick.

Acid Proofing Bitumor Mastic

Acid proofing bitumor mastic is employed in petrochemical plants, steel mills, and a variety of other areas. The top producer obtains the highest product quality, therefore supplying the optimum security problem against the threats associated with acid dealing.

Acid Proofing Bitumor Plaster

Furthermore, people who operate with such hazardous substances should use an acid proofing bitumor primer to assist them to prevent the harmful impacts of alkaline solutions. It is the greatest way to avoid erosion and the caustic character of acid and alkalis.

Conclusion

Acid proof lining materials are extremely important, thus they should be bought from an acid proof lining material & acid resistant material manufacturer who is well-versed in dealing with such items.

This is something we are proud of. The produced items should have a strong resistance to any raw acid and hence have the least corrosion impact. And acids are required chemicals in the majority of industrial belts.

As a result, the use of the acid must also be done correctly. Such materials may be used in a wide range of sectors, including iron and steel, manufacturing, and building.