Selecting the right refractory materials is essential for industries that operate under extreme heat. Steel mills, cement plants, petrochemical facilities, and power stations depend on linings that can withstand temperatures above 1600°C while resisting slag attack, abrasion, and thermal cycling.

A strong understanding of refractory classification helps engineers make better choices, avoid costly downtime, and extend furnace service life.

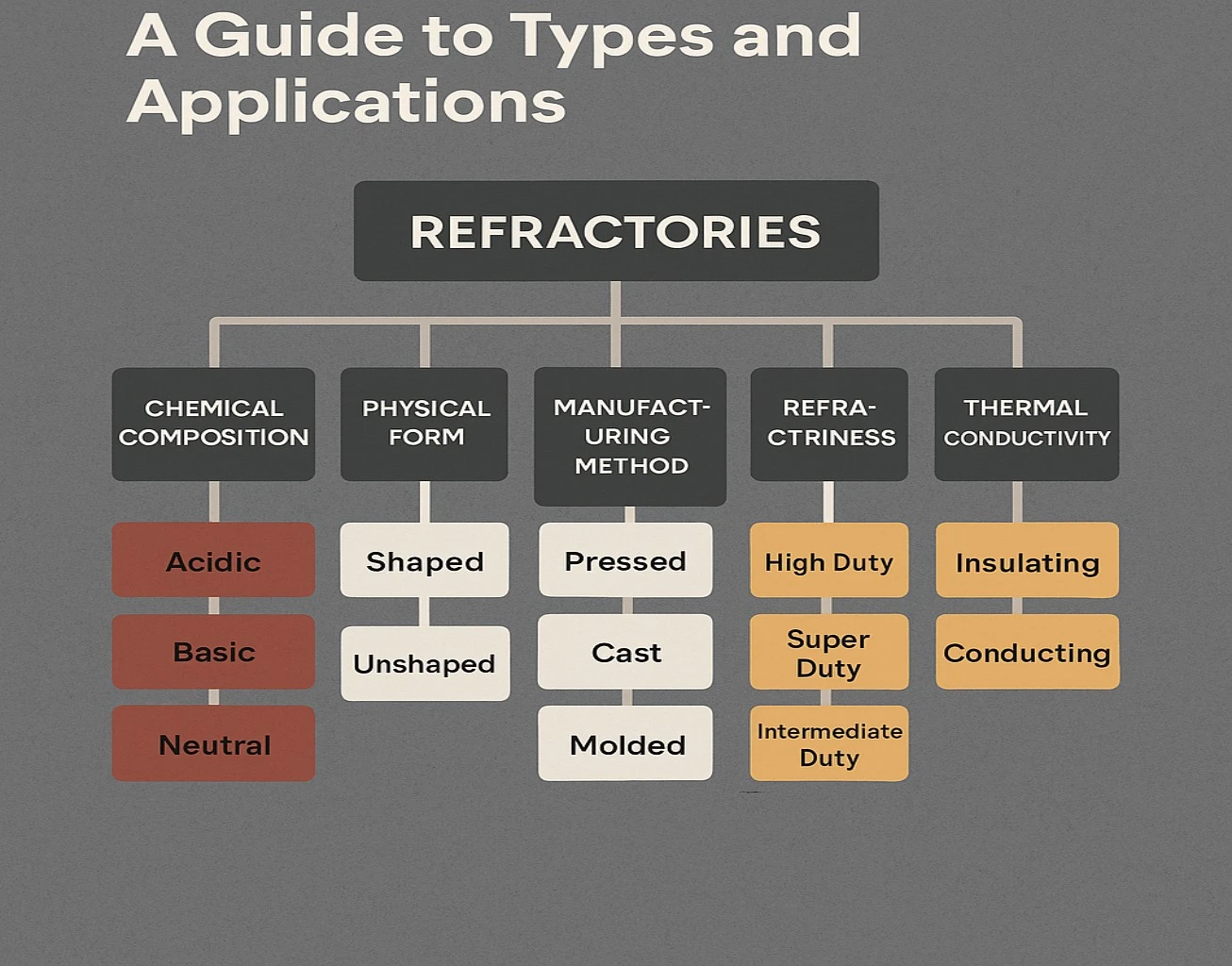

This guide explains the types of refractory materials, how they are classified by composition and form, and what factors to consider when choosing materials for high-temperature applications.

Key Highlights

- Clear refractory classification guide with major categories

- Overview of refractory types and applications in industries

- Classification of refractories by composition

- Refractory classification by shape and form

- Insights into refractory materials used in furnaces

- Supplier and installation considerations

Understanding the Classification of Refractories by Composition

Acidic Refractories and the Role of Silica

Silica refractories are rich in silicon dioxide, often exceeding 90%. They are ideal for glass furnaces, coke ovens, and acid steelmaking because of their stability in acidic environments. They also have a self-healing property under certain slags. However, they degrade quickly when exposed to basic slags and require careful allowance for thermal expansion.

Basic Refractories with Magnesia-Carbon Bricks

Magnesia-carbon bricks combine the chemical stability of magnesia with the thermal shock resistance of carbon. This innovation changed steelmaking, especially in electric arc furnaces where high thermal cycling and slag penetration are common. Magnesia resists basic slags rich in lime and iron oxide, while carbon prevents spalling during rapid heating and cooling.

Neutral Refractories and Alumina Performance

Alumina refractories fall in the neutral category and are known for versatility. With aluminum oxide content ranging from 45% to 99%, they adapt to both acidic and basic environments. Their strength and shock resistance make them suitable for rotary kilns, blast furnaces, and petrochemical reactors.

Refractory Classification by Shape and Form

Shaped Refractories such as Bricks and Custom Designs

Bricks remain a classic option where accurate dimensions and durability are needed. Today, shaped refractories are produced with tight tolerances, minimizing gaps that could weaken the lining. Beyond simple bricks, shapes like arches and wedges are designed for specific furnace areas.

Unshaped Refractories for Flexible Installations

Monolithic refractory materials are installed in place, offering flexibility and fewer joints. Common forms include:

- Refractory castable mix – strong, joint-free linings with ultra-low cement grades for higher durability.

- Ramming mass – dense, impermeable linings used in furnace hearths exposed to severe wear.

- Gunning mix – sprayed into place for quick repairs and hard-to-reach areas.

These solutions reduce installation time and adapt to complex configurations.

How Refractory Materials Are Used in Furnaces

Comparing Dense and Insulating Refractories

- Dense refractories have low porosity (<20%) and serve as the main barrier against slag, abrasion, and thermal shock.

- Insulating refractories have higher porosity (45–85%) and conserve energy. They are used mainly as backup linings, not in direct slag contact.

Advances in High-Performance Refractory Materials

New technologies such as spinel-containing refractories, silicon carbide composites, and ultra-low cement castables extend service life. These high-performance refractory materials justify higher costs by reducing downtime and improving operational efficiency.

Kiln Lining Materials for Different Applications

Kiln lining materials must handle high temperatures, cycling stresses, and chemical exposure.

- Cement kilns require resistance to alkaline environments and sudden thermal changes.

- Rotary kilns demand abrasion resistance due to rotating charge materials while also maintaining insulation to reduce energy loss.

The correct material depends on atmosphere, cycling patterns, and the highest operating temperature.

What to Look for in a Refractory Materials Manufacturer

Partnering with an experienced refractory materials manufacturer ensures access to technical support, quality assurance, and proven performance. Reliable suppliers assist with material selection, installation guidance, and maintenance planning.

Reputable providers, like Ganeshas Refractory, are trusted for their expertise across different industries.

Why Precast Refractory Materials Suppliers Are in Demand

Precast solutions are gaining popularity as plants look to reduce downtime. Components are manufactured under controlled factory conditions, ensuring quality and consistency.

A precast refractory materials supplier can deliver complex shapes that would be difficult to form on-site, saving installation time and improving safety.

Frequently Asked Questions

How are refractories classified by chemical composition?

They are classified as acidic (silica-based), basic (magnesia-based), or neutral (alumina-based) depending on their oxide content and reaction to slags.

What’s the difference between refractory bricks and castable refractories?

Bricks are pre-formed shapes, while castables are mixed and installed in place to create joint-free linings.

When should I use insulating refractories vs dense refractories?

Use dense refractories in contact with slag or heavy wear, and insulating refractories as backups where heat conservation matters most.

What properties matter most when selecting a refractory?

Key factors include refractoriness, thermal shock resistance, chemical compatibility, strength, and thermal conductivity.

How long do refractory linings last?

Lifespans vary from months to years depending on service severity, quality of installation, and maintenance practices.

Final Thoughts

Understanding refractory classification is critical for choosing materials that balance durability, energy efficiency, and cost. By considering refractory types and applications across composition, shape, and performance, industries can extend furnace life and reduce unplanned maintenance.

From silica refractories to magnesia-carbon bricks, and from monolithic refractory materials to specialized kiln lining materials, the options are extensive. Success depends on aligning the right product with the operating environment and working with a trusted refractory materials manufacturer.