Phoscast-90XR

Rate INR/Piece

![]() Whatsapp:

Whatsapp:

+91 96620 13109

![]() Email:

Email:

sales@ganeshas.net

Product Description

GANESHA’S has taken a number of approaches to identify the key factors affecting erosion rates with an objective to enhance the life of inbed tubes as well as implementing the corrective action to reduce the erosion rates.Phosphate coatings are often used to protect steel parts against rusting and other types of corrosion.Erosion of inbed coils in fluid bed combustor is an unavoidable phenomenon however the rate of metal wastage and thus the life of tubes depends on various factors like ash & fuel properties, design of Combustor/feeding system, flue gas velocities operating conditions, etc. It has been also observed that maximum erosion-prone inbed coils are those which come above fuel feed nozzles and an area of approximately 1 to 1.5 mts around fuel feed systems are badly affected customers using FBC boilers (Particularly underbed feed FBC boilers) for the protection of inbed coils against erosion potential by applying highly abrasive resistant refractory on inbed coils above the fuel feed system.

APPLICATION

Phoscast-90 XR can be applied by ramming with a wooden mallet having an adequately large head @” dia x 5″ length x 10” Jong handle). The desired lining or repair thickness is built up in several courses while ramming the mass to a uniform thickness. Phoscast refractory should never be trawled to obtain a smooth surface; ramming only should finish the surface. Any excess mass is to be sliced off with a trowel edge and then finished by ramming again for the bed coil. Tube application of AFBC boiler, the material pasty mass should be finger pressed into the studs of the tube with maximum force. The finish should be given by pressing the hand palm against the material applied, using surgical type thin rubber hand gloves.

Features:

Characteristics:

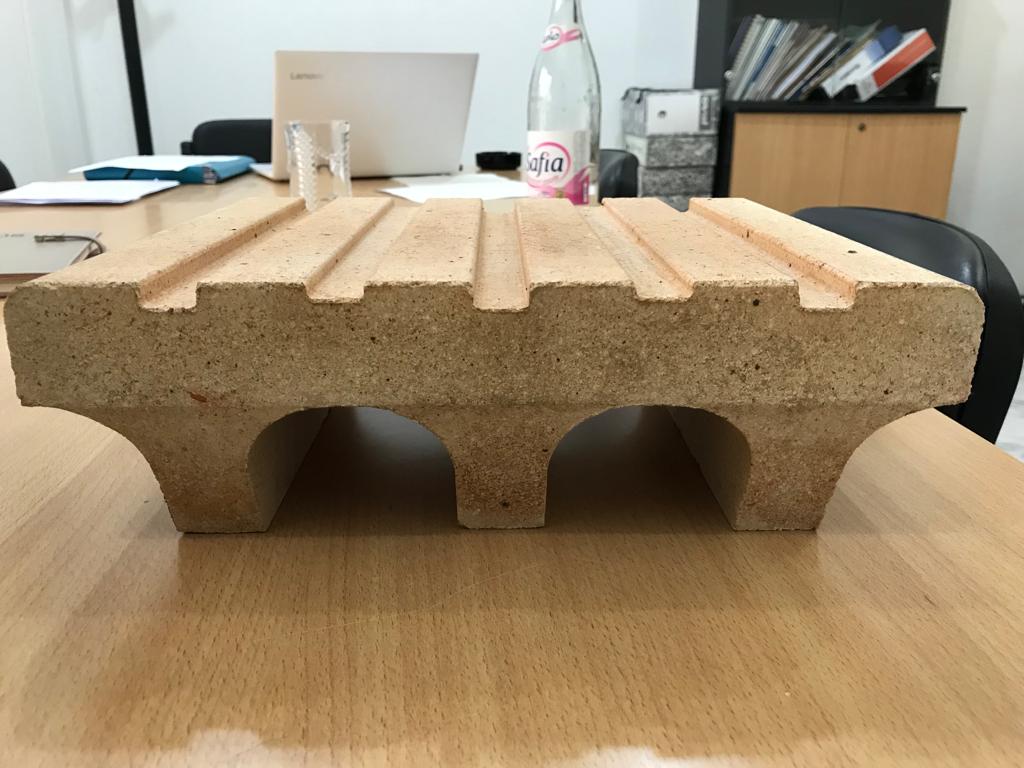

- Material: – Refractory Castable

- Type: 90% Alumina Dense Castable

- Nature of Bond:- Chemical

- Installation:- Vibration Casting

- Max. Service Temperature:- 1700°C

- Maximum Grain Size:- 3.5 mm

- Water required for casting:- 10.60 to 11.80%

Product details: