The following are the various types of refractory materials used in a wide range of industries, from the steel industry to the cement industry, refractory materials played a significant role in industrial businesses.

Types of Refractory Materials and Their Uses:

Fired Refractory Products

Fired refractory products are materials that can withstand heat and thermal shock resistance without interfering with mechanical properties like refractory bricks, castables, mortars and so forth. In addition, such refractory materials are used in boilers, furnaces, ovens etc. Fired refractory materials consist of using various refractory manufacturing methods like kneading, moulding and drying.

Non-Fired Refractory Products

On another side, non-fired refractory is one of the main types of refractory materials that are obtained from different materials like granular powdered refractory materials and binders that don’t demand the use of fire. In addition, non-fired refractory products are used in the steel, cement, power generation industry and petrochemical industries.

Special Refractories

Special refractories are another main type of refractory material that offers special properties for special applications than standard refractory materials. In addition, special refractories are specifically designed for extreme operating conditions such as chemical corrosion, high temperature and mechanical abrasion.

Monolithic Refractories

Monolithic refractories are one of the best-selling types of refractory material that have an accurate gradation of granular, powdery raw materials, binders and other admixtures that do not demand high temperatures. Monolithic refractors are widely known for their superior qualities and thermal properties that make it suitable to use in high-temperature applications.

Functional Refractory Bricks

Functional refractory materials are a subset of refractory materials that are combined with binders, powdered, and granulated refractory raw materials to take on a specific shape. Functional refractory materials can withstand extremely high heat-temperature as well as harsh environments. In addition, these types of materials have high melting points, low thermal conductivity and good chemical stability.

Plastic Refractories

Plastic refractories are made up of various grades of refractories, binders, water, plasticizer and other admixtures. In addition, such types of refractory materials are known as shapeless refractory materials which provide great plasticity for a long time. Plastic refractories are widely used in industrial furnaces, certainly roof furnaces or furnace linings.

Casting Materials

Casting materials are types of refractory materials that are ideal to use in monolithic refractory materials. Additionally, it is also suitable for various industrial furnaces due to its good fluidity and easy-to-pour moulds. Casting materials are made up of aggregates, cement, powder and other admixtures.

Clay Bricks

Clay bricks are one type of aluminium silicate refractory materials obtained from mullite, glass phase and cristobalite with an AL203 content of 30% to 48%. In addition, clay bricks are the best-selling refractory material in the cement industry. They are commonly used in glass kilns, rotary kilns, furnaces and other applications. Further, clay bricks are also used for building construction purposes.

High Alumina Bricks

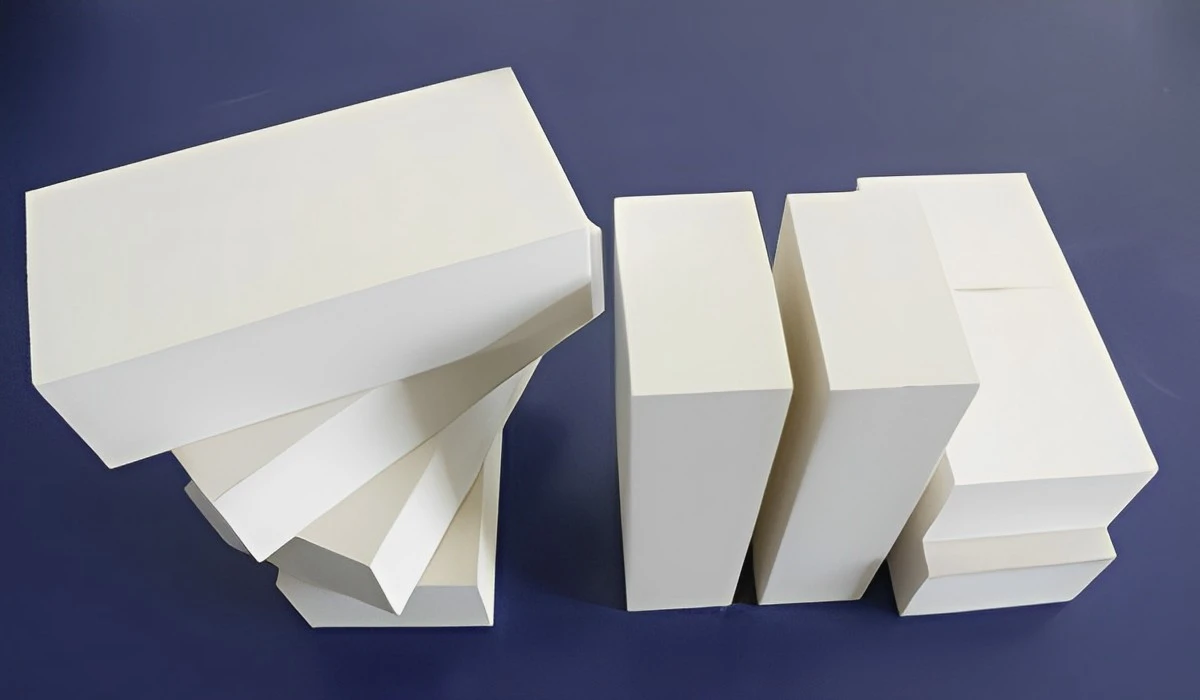

High Alumina bricks are also one of the common types of refractory materials that have an AL3 content of more than 48%, such bricks are made up of corundum, glass and mullite. In addition, high alumina refractory materials can withstand high-temperature applications above 1600 degrees Celsius. They are widely used in the cement industry, steel industry, petrochemical industry and so forth where high temperatures and harsh environments are common.

Silica Bricks

Silica bricks are one of the best refractory materials on the market; they are made up of phosphorous quarts, residual quartz, cristobalite, and glass, and have a SiO2 content of more than 93%. Furthermore, silica bricks are commonly used to build the partition walls of cooking oven carbonization and other similar applications.

Ramming Materials

Ramming Materials are a type of refractory materials that are widely used in industrial furnaces, ovens and kilns. These materials are obtained from the certain sizes of refractory materials, binders and additives by using the ramming method.

Magnesium Bricks

Magnesium bricks are a kind of refractory bricks that are made up of alkaline refractory materials; formed from sintered magnesia or fused magnesia as raw materials. Additional types of refractory materials are primarily used in open-hearth furnaces, electric furnaces and other types of industrial furnaces.

Corrodum Bricks

Corundum bricks are also referred to as refractory with more than 90% of alumina content and corundum materials as the main part. Additionally, corundum bricks are majorly used in blast furnaces, sliding nozzles and so on.

Bottom Line:

Ganeshas is one of the leading manufacturers of refractory materials in India, meeting various industries’ refractory needs. Whether you are someone searching for uncompromised quality refractory materials at the best price, get in touch with our team to know further product details.