As you may know, rotary valves and rotary airlock valves play an important role in material handling and transferring from the architectural to the industrial sectors, but the most contentious discussion begins with whether they are the same or not. Here, we have compiled all the data you need to be aware of in order to assist you in finding a simple and direct solution. So without further ado, let’s jump into it to get the conclusion; rotary valve vs rotary airlock valve.

Rotary Valve & Rotary Airlock Valve?

As we know, rotary feeders and rotary valves are other terms for Rotary Airlock Valves. These types of valves are suitable for both vacuum and pressure pneumatic conveying systems. These valves’ primary job is to act as a lock that stops air leakage, but they also serve as an essential product that handles various other functions.

In other words, the efficiency of a conveying system depends on the rotary feeders. Note that not all rotary valves are necessarily rotary airlock valves, but all rotary airlocks are functionally air valves.

What are the Uses of a Rotary Valve vs a Rotary Airlock Valve?

Rotary valves also known as rotary airlock valves, they both widely used in various industries for different purposes. However, one of the main reasons they are in demand for material handling and transportation by controlling the flow of granular or powdered materials.

Moreover, Rotary valves are also employed in dust collection systems to get rid of dust and other pollutants in the environment. Additionally, rotary valves are specifically designed to maintain constant pressure in the system and prevent air from flowing backward.

Overall, such types of two-face valves are commonly used in pneumatic conveying, dust control equipment like dust collector systems, and other industrial vacuum systems. Therefore both are essential components in several industrial sectors like food, pharmaceutical, refractory, steel-iron, and so forth.

What are the Functions of Rotary Valve & Rotary Airlock Valve?

Rotary valves and rotary airlock valves have two main functions: metering-feeding, and airlock sealing. This makes them control the flow of materials into a processing system or equipment at a consistent rate to prevent air or gas leakage between different environments.

In addition, it can also be used to isolate material flow between different processing stages by maintaining the efficiency of product quality and equalising pressure between different environments.

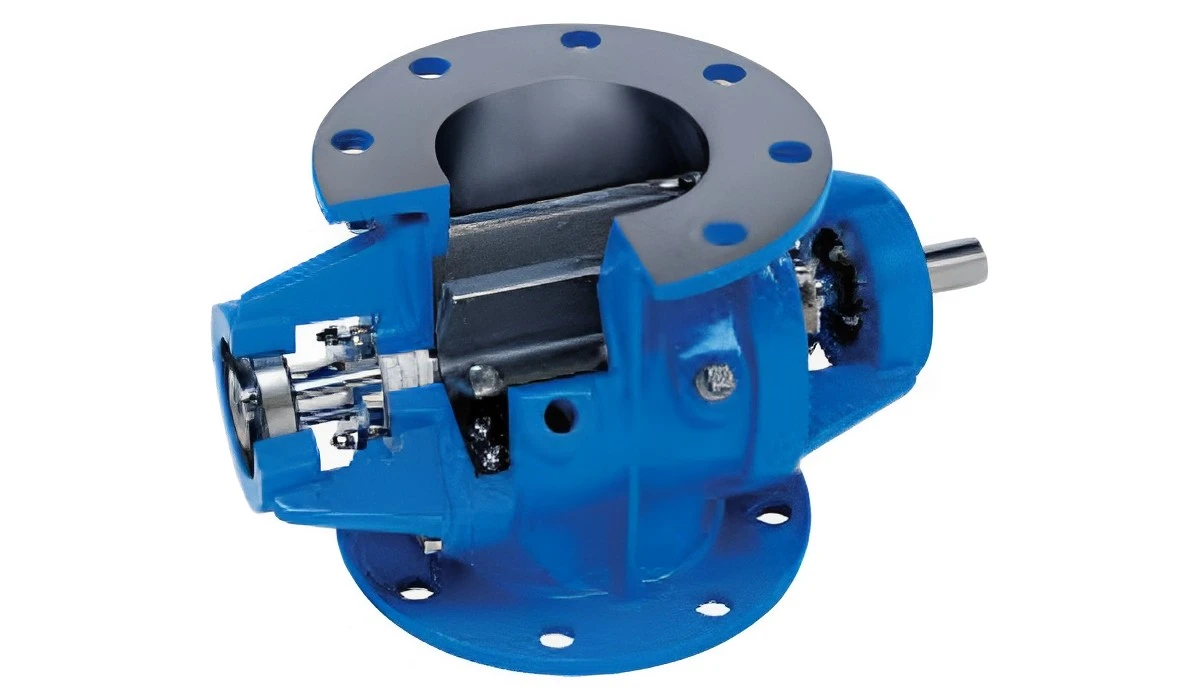

The way they both work is by using a rotating rotor that comes with blades or vanes that make a smooth moving process of material from one chamber to another. As the rotor continues to rotate, the material is fed into the valve through one port and discharged through another. After that, the rotor vanes create a seal between the inlet and outlet ports, preventing material leakage and maintaining pressure between different environments. Thus, that’s how the specific design and operation of the valve will depend on the specific application and material being handled.

What Makes Rotary Valve Function Standout From Other Valves?

Several types of valves are available in the market, but not all of them can stay in demand like rotary valves. The following are the impressive features of the Rotary valve aka rotary airlock valve function that makes them stand apart from other valves

Features of Rotary/Airlock Valve Function:

– High accuracy and precision in controlling material flow.

– Better durability and reliability.

– Resistant to corrosion and wear.

– Prevents contamination

– Preventing air and gas from escaping

What are the Advantages & Disadvantages of Rotary Airlock Valves/Rotary Valves?

Here, we listed out the advantages and disadvantages of a rotary airlock valve aka rotary valve, that you should keep in mind before purchasing one.

|

Advantages |

Disadvantages |

| High-Efficiency System | Limitation in Pressure |

| Outstanding Material Handling | Limitation in Temperature |

| Minimal Material Leakage | Quiet Expensive |

| Ease of Maintenance | Noisy |

| Simple Using Method | Needs Plenty of Lubrication |

Conclusion:

In conclusion, it is safe to say that rotary airlock and valve have quite the same functions and it’s a 19-20 difference which is about design and purpose. The rotary valves are valves without a home that makes them suitable for metering and feeding. The rotary airlock valve, however, simplifies the process of sealing air.

Moreover, if you are one of those finding high-quality refractory materials and mechanical products like rotary airlock valves or feeders, get in touch with us. Ganeshas is a leading refractory manufacturer in Ahmedabad offering quality at the best competitive price.