When most people think about bricks, they picture construction materials for buildings. However, there’s a specialized category of bricks that operates in environments so extreme they would reduce ordinary materials to ash. These are refractory bricks, and their applications span from massive industrial operations to the cozy pizza oven in your favorite restaurant.

Refractory bricks serve a much wider range of purposes than most people might expect. These heat-resistant materials form the backbone of countless industries, quietly enabling processes that shape our modern world. Let’s explore where these thermal warriors prove their worth and why they’re absolutely essential.

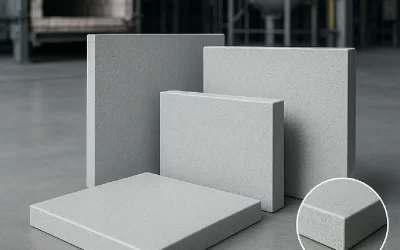

What Makes Refractory Bricks Special?

Unlike regular building materials, refractory bricks contain specialized compounds like alumina, silica, and magnesite. These elements make them incredibly tough against high temperatures, chemical exposure, and sudden changes in temperature.

The composition varies significantly depending on the intended use. For instance, what fire bricks are made out of can include high-alumina content for steel applications or silica-rich formulations for glass manufacturing. This customization allows engineers to match the brick properties precisely to the operating conditions.

Industrial Powerhouses: Where Heat Meets Engineering

Steel and Metallurgy Operations

In blast furnaces reaching temperatures above 1500°C, refractory fire bricks create protective barriers that contain molten metal and slag. These applications demand materials that can withstand not just extreme heat, but also chemical corrosion from aggressive molten materials.

Steelmaking equipment like ladles, tundishes, and converters all rely on carefully engineered refractory linings. Without proper protection, these vessels would fail within hours of operation, making quality refractory materials absolutely critical for continuous production.

Cement Manufacturing

Cement kilns operate in a unique environment where temperatures reach 1450°C while handling abrasive materials. Fire bricks are used for lining rotary kilns, coolers, and preheater zones. The challenge here involves both thermal protection and resistance to chemical attack from alkaline cement compounds.

Refractory castable materials often complement shaped bricks in cement applications, filling irregular spaces and providing seamless linings in complex geometries.

Specialized Applications Across Industries

| Industry | Primary Use | Key Challenges |

| Glass Manufacturing | Furnace linings, regenerators | Chemical attack from molten glass |

| Petrochemicals | Reformer tubes, cracker furnaces | High temperature + chemical exposure |

| Power Generation | Boiler linings, combustion chambers | Thermal cycling + ash abrasion |

| Foundries | Melting furnaces, holding ladles | Repeated heating/cooling cycles |

Glass Production Challenges

Glass furnaces present unique challenges because molten glass is chemically aggressive at high temperatures. Refractory bricks are used for critical areas like tank walls, regenerators, and working ends. The bricks must resist both thermal shock and chemical erosion from glass vapors.

Quality refractory materials in glass applications directly impact product quality and furnace campaign life, making material selection crucial for economic operation.

Petrochemical Refineries

Oil refineries operate some of the most demanding thermal processes in industry. Reformers, crackers, and flare stacks create environments where use of refractory bricks becomes essential for safe operation. These applications often combine extreme temperatures with exposure to hydrogen, hydrocarbons, and other reactive chemicals.

The combination of thermal and chemical stresses requires carefully selected materials that maintain structural integrity over extended operating periods.

Beyond Heavy Industry: Everyday Applications

Food Service and Culinary Arts

Fire brick uses extend into commercial kitchens and artisan food preparation. Traditional tandoor ovens, wood-fired pizza ovens, and specialty baking equipment rely on refractory materials for heat retention and even temperature distribution.

These applications demonstrate how refractory technology benefits everyone, not just industrial operations. A perfectly baked pizza depends on the same thermal principles that enable steel production, just at a smaller scale.

Waste Management Systems

Municipal incinerators handle diverse waste streams while maintaining high combustion temperatures. The combination of varying fuel types and corrosive gas production creates challenging conditions where fire bricks are used for protecting combustion chamber walls and maintaining operational safety.

Castables and Custom Solutions

Traditional shaped bricks continue evolving alongside newer refractory castable technologies. Castables offer installation advantages in complex shapes while providing comparable performance to conventional bricks. This flexibility allows engineers to optimize refractory systems for specific applications.

The choice between shaped bricks and castables often depends on geometry, installation constraints, and maintenance requirements. Both technologies serve essential roles in modern thermal engineering.

Every application demands careful material selection based on operating conditions, chemical exposure, and thermal cycling patterns. A brick that excels in steel ladles might fail quickly in glass tank applications.

Looking Forward

The uses of refractory bricks continue expanding as industries push operational limits and develop new processes. From traditional steel and cement production to emerging technologies in energy storage and advanced manufacturing, these materials remain essential for high-temperature applications.

At Ganeshas, we recognize that successful refractory solutions require a deep understanding of both materials science and application requirements. Whether specifying shaped bricks, castables, or custom-engineered solutions, the right choice makes the difference between reliable operation and costly failures.