Walk into any chemical plant, lab, or factory, and you’ll see one thing that stands out: the floor. It’s not just the foundation beneath your feet; it’s the silent shield that protects your workplace from harsh acids, alkalis, and chemical spills. In environments where a single drop of acid can cause damage worth thousands, investing in the right acid resistant tiles for industries isn’t optional; it’s essential.

Choosing acid-resistant tiles for your factory or industrial space is simple if you know what matters most. These tiles, sometimes called acid proof tiles, chemical-resistant tiles, or anti-corrosive tiles, protect your floors from harsh chemicals, strong cleaning agents, and heavy machinery, keeping your workspace safe and looking new for years.

Let’s break down exactly what you should look for before buying acid resistant tiles.

Key Takeaways

- Low Porosity = Longer Life – Always pick non-porous floor tiles, vitrified tiles with < 0.5% water absorption.

- Dual Resistance is a Must. Choose acid alkali resistant tiles for all-around protection.

- For factories and warehouses, go with heavy duty industrial tiles.

- Always buy from a trusted Acid / Alkali Resistant Tile Manufacturer and Supplier in India.

What Acid-Resistant Tiles Really Mean?

When you see terms like acid resistant tiles, acid alkali proof tiles, or acid alkali resistant tiles, they all refer to industrial-grade materials built to withstand continuous exposure to acids, alkalis, and corrosive chemicals.

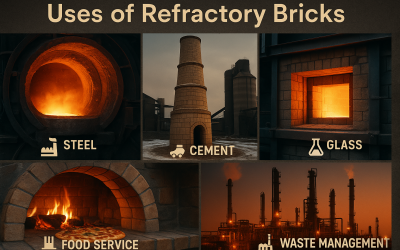

These are not your everyday decorative floor tiles. They are acid resistant floor tiles, also known as chemical proof tiles, designed for high-pressure, chemical-intensive environments, from fertilizer plants and battery rooms to food processing units and refineries.

As per Indian Standard IS 4457:2007, high-quality industrial acid resistant tiles must have a water absorption rate of less than 0.5%, ensuring a dense, non-porous structure that resists both acid and alkali penetration.

Checklist for Buying Acid-Resistant Tile for Industries

Buying acid resistant tiles isn’t just about picking the right color or size; it’s about understanding the material’s chemistry, performance, and suitability for your environment. Let’s look at the most important acid resistant tiles properties you must evaluate before investing.

Water Absorption Rate (Porosity)

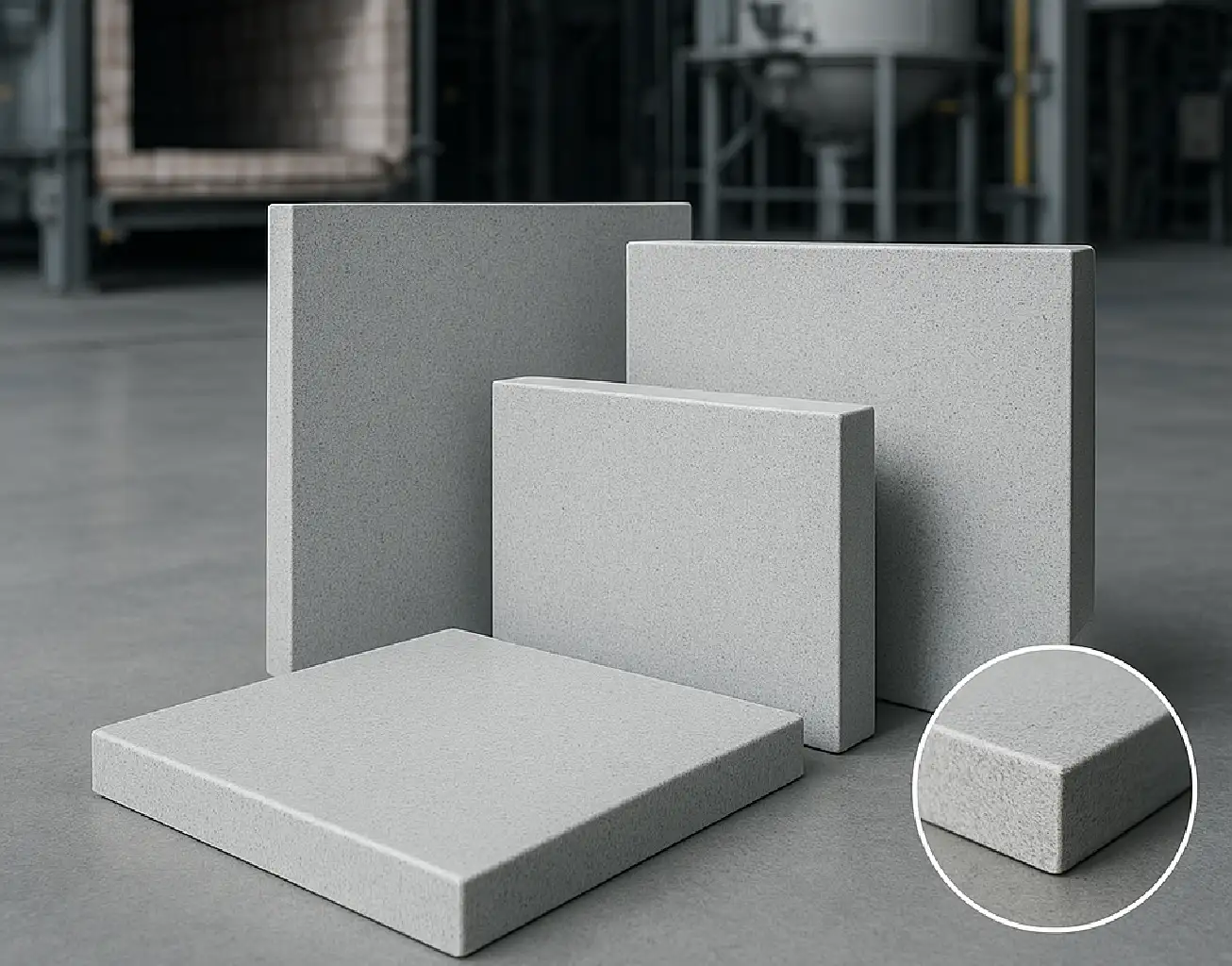

One of the first parameters to assess is porosity, which defines how much liquid the tile can absorb. The lower the porosity, the higher the chemical resistance. Industrial refractory flooring solutions must have water absorption of ≤ 0.5% in order to prevent corrosive acids or alkalis from seeping into the surface and damaging the sub-floor.

Acid and Alkali Resistance

The most critical feature is how well a tile resists chemical attack. A high-quality tile should remain unaffected when exposed to strong acids and alkalis. These tiles are specifically tested to ensure they can withstand both acidic and alkaline conditions without surface erosion or weight loss.

Mechanical Strength & Load Bearing

Your flooring isn’t just fighting chemicals; it also battles pressure and impact every day. Forklifts, drums, and heavy machinery exert tremendous stress. That’s where heavy-duty industrial tiles shine. Choose high pressure resistant flooring tiles for areas with constant movement and heavy impact.

Abrasion and Scratch Resistant

Industrial floors experience constant wear from dragging pallets, rolling barrels, or metal contact. Over time, weak tiles lose their surface glaze and develop cracks that trap chemicals. The longer the tile maintains its smooth finish, the lower your maintenance costs and risk of corrosion.

Dimensional Accuracy & Thickness

Uniform size and thickness are critical for industrial tile installation. Variations can lead to uneven surfaces, creating chemical puddles or mechanical imbalance. Proper thickness ensures mechanical stability, uniform load distribution, and longevity of the acid resistant tiles for factories.

Material Composition

Among various materials, red shale acid resistant tiles are renowned for their durability and chemical performance. Some advantages of Red Shale Acid Resistant Tiles include high compressive strength, uniform texture and density, and long life even under extreme chemical attack.

Installation Compatibility

Even the best acid resistant tiles can fail if installed with ordinary cement mortar.

- Use acid-resistant mortars or epoxy-based adhesives.

- Maintain proper joint width (3–5 mm) and chemical-resistant grout.

Poor bonding leads to cracks, seepage, and eventual corrosion. Always work with professional installers who understand industrial flooring materials and standards.

Why Does It Matter?

Did you know? According to industry research, acid-resistant flooring solutions can reduce annual maintenance costs by up to 40% compared to traditional concrete floors. When installed properly, acid resistant tiles for factories can last 10 – 20 years, even under constant exposure to corrosive chemicals. The key is correct installation, using chemical-proof mortars, proper jointing, and following certified industrial tile installation methods.

Conclusion

In industries where every chemical reaction counts, your flooring shouldn’t be the weakest link. Acid resistant tiles are the silent heroes that protect your facility, employees, and investments from unseen chemical damage. From anti-acid tiles for factories to high-pressure resistant flooring tiles, every choice impacts performance and safety.

Ready to protect your factory floor with long-lasting, acid-proof solutions? Contact Ganesha’s Refractory today for a free on-site assessment and customized quote.

Frequently Asked Questions

What should I look for when buying acid-resistant tiles?

Look for low porosity, chemical resistance (acid + alkali if needed), mechanical strength, appropriate thickness, anti‐slip finish, proper installation. Also ensure the tile is labelled for industrial use.

Are acid-resistant tiles different from chemical-resistant tiles?

Acid resistant tiles focus on resistance to acids (and often alkalis). Chemical resistant tiles are a broader term covering resistance to acids, alkalis, solvents, oils, and chemicals in general.

How thick should acid-resistant tiles be for industrial use?

Thickness depends on load, traffic, substrate, and chemical environment. Some specification sheets list thicknesses of 10 mm, 12 mm, 15 mm, 20 mm for tiles; for extremely heavy duty use, bricks up to 38mm or 75mm.

How long do acid-resistant tiles last?

If correctly specified, installed, and maintained, they can last many years. Durability depends on actual chemical exposure, mechanical wear, installation quality, and maintenance.