All refractory materials are made from fire clay, which contains silica and alumina. In fact, fire clay is used to make all high heat-resistant firebricks. The roots of various items, such as heat resistant binders, coating, pottery, ceramic materials, or ceramic tiles on the space shuttle, begin with fire clay, which melts at 1600°C or 2912°F. Only specific production processes of those pricey materials alter their characteristics and their applications.

What Are Fireclay Bricks?

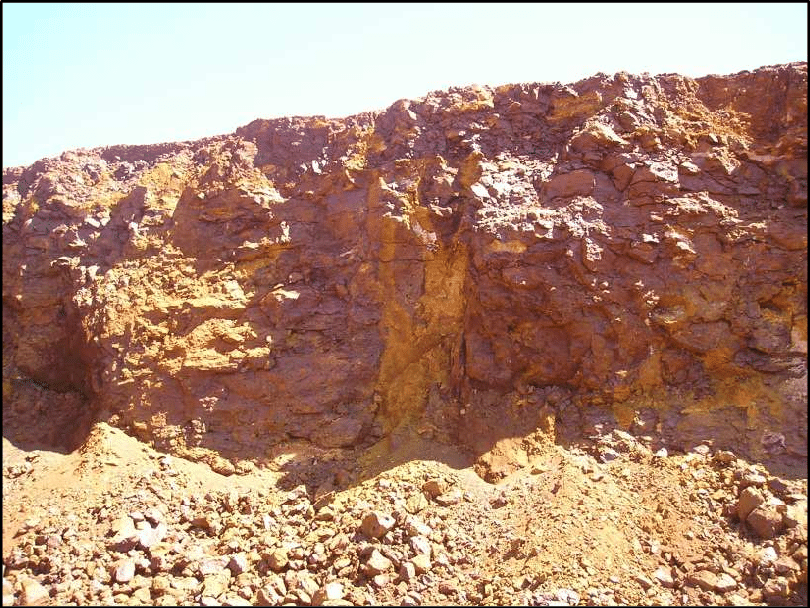

A close-up of fire clay. Simply said, fire clay is a mud with a greater Alumina (AL) concentration than regular mud. Usually has a whiter-lighter tone. Pinkish, light brownish, whitish to yellowish It’s also very affordable. It is available from refractory or pottery vendors. Even when it is in the form of dry powdered fire clay in sacks, it is still quite heavy (physical properties calculators for various refractory clay materials.) If you get the clay in dry powdered form, you just need one bag per roof. Alumina concentration of fire clay typically varies within 24 and 34 percent Al and Silica content is around 50 to 60%.

Even in a dry powdered state with a density of 1.303 gram/cm3 or approximately 0.753 ounce/cu-in, fireclay is a hefty product when compared to cement, for example. That is something I notice every time I raise the luggage. Measuring units may be readily converted/calculated using this online fire clay volume vs. weight calculator.

What Is It Made of?

A firebrick’s chemical makeup is composed of 73% silica and 23% alumina. The remainder is made up of titanium, ferric oxide, and other metallic oxides. Regular brick is mostly composed of alumina, silica, magnesia, lime, iron oxide, lime, alkalies & alumina.

Uses Of Fire Clay

Fireclay bricks are stable at extreme temperatures, with fusion points more than 1,600°C. Hence, it is excellent for lining furnaces as fire brick, as well as the construction of metalworking equipment such as retorts, saggars, crucibles, and glassware.

Clay that is burned quickly must be completely dry before it reaches the temperature at which steam forms. When firing without a kiln, pre-drying your clay pieces in a home oven set to 190 degrees Fahrenheit may help.

Fire Clay Refractory!

Fire clay is a broad word that refers to sedimentary or residual clays that vitrify at extremely high temperatures and, when burned, exhibit exceptional heat resistance.

These are excellent hydrated silicates of alumina with a high proportion of alumina (20-35%), silica (55-75%) iron oxide (2-5%), and approximately 1% lime, alkalis & magnesia. The higher the alumina content, the more resistant the clay. Fireclay refractory can withstand extremely high temperatures of up to 1700°C without melting or softening, and they are resistant to debonding. A little amount of magnesia & lime, as well as alkalis, assist to melt the clay pieces more strongly, but a high amount of magnesia & lime tends to melt the clay at low temperatures. Iron oxide and other alkalis degrade the refractory properties of fire clay.