Industries are threatened by a range of airborne particles like dust, trash, and other granular particles or powder. In addition to causing health problems, especially for the respiratory system, it also affects workplace property. A solution to enhance the air quality of industrial buildings is therefore highly desired.

Hence, never overlook the effectiveness & usefulness of the purported dust collectors when considering an investment in such systems. These adaptable tools have been discovered to be really useful in raising the quality of air released and so contribute to keeping a safe, pollution-free atmosphere. Without further ado, let’s get started learning more about industrial dust collection systems and dust collectors.

What is an Industrial Dust Collection/Dust Collector System?

Industrial dust collection or dust collector systems are designed to improve commercial or industrial air quality by capturing particulate matter. To combat air pollution, the government banned pollutants and solid particles that they filter and trap.

Manufacturing particles are toxic and can cause respiratory harm as well as other health issues. By collecting them, dust collection systems change tainted air using a network of filters or separators.

These systems are commonly used in industries where dust is generated, including mining, pharmaceutical production, electronics assembly, glass manufacturing, chemical processing, metal fabrication, printing, power generation, construction, automotive repair, paint spray booths, woodworking, etc.

Types of Industrial Dust Collector Systems:

Industrial dust collector systems are divided into two categories; Wet dust collectors & dry dust collectors. Wet dust collectors use water sprays to capture particles suspended in the air stream. Dry dust collectors use electrostatic precipitation technology to collect particles. Both types of dust collectors have their advantages and disadvantages. In addition, there are other sub-types of industrial dust collector systems.

– Cyclone dust collectors

– Explosion-proof dust collectors

– Inertial separators

– Jet dust collectors

– Cartridge dust collector

– Baghouses

– Downdraft tables

– Fabric filters

– Spark arrestors

– Wet scrubbers

– Portable dust collectors

– Electrostatic precipitator

– Industrial dust collectors

Working Process of Industrial Dust Collector Systems:

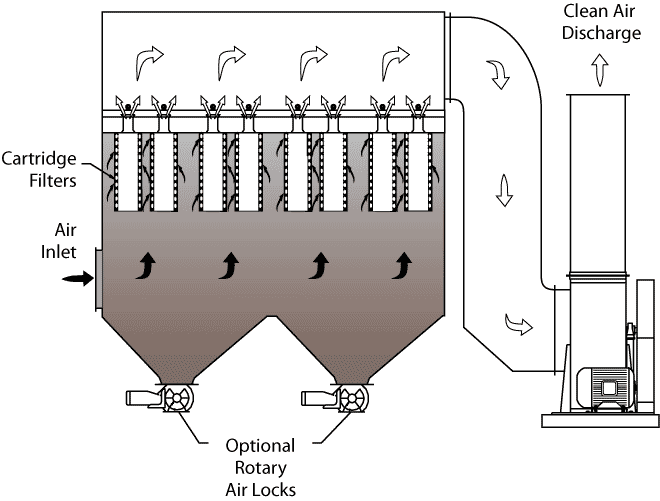

The working process of industrial dust collector systems begins with the flow of air. Air flows through the ductwork of the building. As the air moves through the ductwork, it picks up dust particles. When the air reaches the intake of the dust collector, it enters the machine. Inside the machine, the air passes through the filter. The filter captures the dust particles. Once the dust particles are trapped, the air continues to pass through the filter until the pressure drops below a certain level. At this point, the air stops flowing through the filter. The air now contains only dust particles. The air exits the machine and travels back to the building.

Once the air returns to the building, it goes through the exhaust ductwork. Here, the air is forced out of the building. Because the air is no longer moving, it does not pick up any additional dust particles.

Benefits of Industrial Dust Collector Systems:

Dust collectors are machines that remove fine particles from air streams. These systems are frequently employed in industrial settings where they are used to gather dust and waste materials from production processes.

Improve health & safety

A dust collector can collect dust on or near equipment, which can pose a fire hazard. In addition, dust collectors improve health and safety by removing these pollutants from the air.

Suitable for all industries & sectors

Many industries use dust collection systems, from grinding machines, transfer belts, or other dust-emitting machines, to the demolition of concrete on roads and bridges.

Boost productivity

The accumulation of dirt, dust, or debris inside equipment can interfere with its mechanics. With dust collectors, this risk is removed, allowing your machinery to work at its best.

Compliance with government regulations

In addition to government regulations, compliance with them is one of the most important motivations for installing a dust collection system.

Find Standard Quality Dust Collector Systems:

By removing dust and other pollutants from the air and environment, an industrial dust collector/dust collection system improves the quality of air emitted from industrial and commercial processes. Ganeshas manufactures a number of dust collectors in accordance with industry standards.

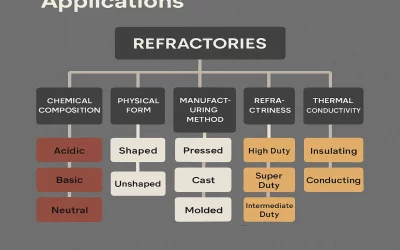

Additionally, we offer custom design, manufacturing, implementation, and installations of dust collectors, dust collection systems, hoods, ducts, blowers, chimneys, and other accessories for our customers in the food & pharmaceutical industry, the woodworking industry, as well as other businesses handling and manufacturing bulk powders and looking for dust control systems. Due to the fact that Ganeshas is a major manufacturer of mechanical and refractory materials. Ganesha products are produced with the highest standards of quality, effectiveness, and security.