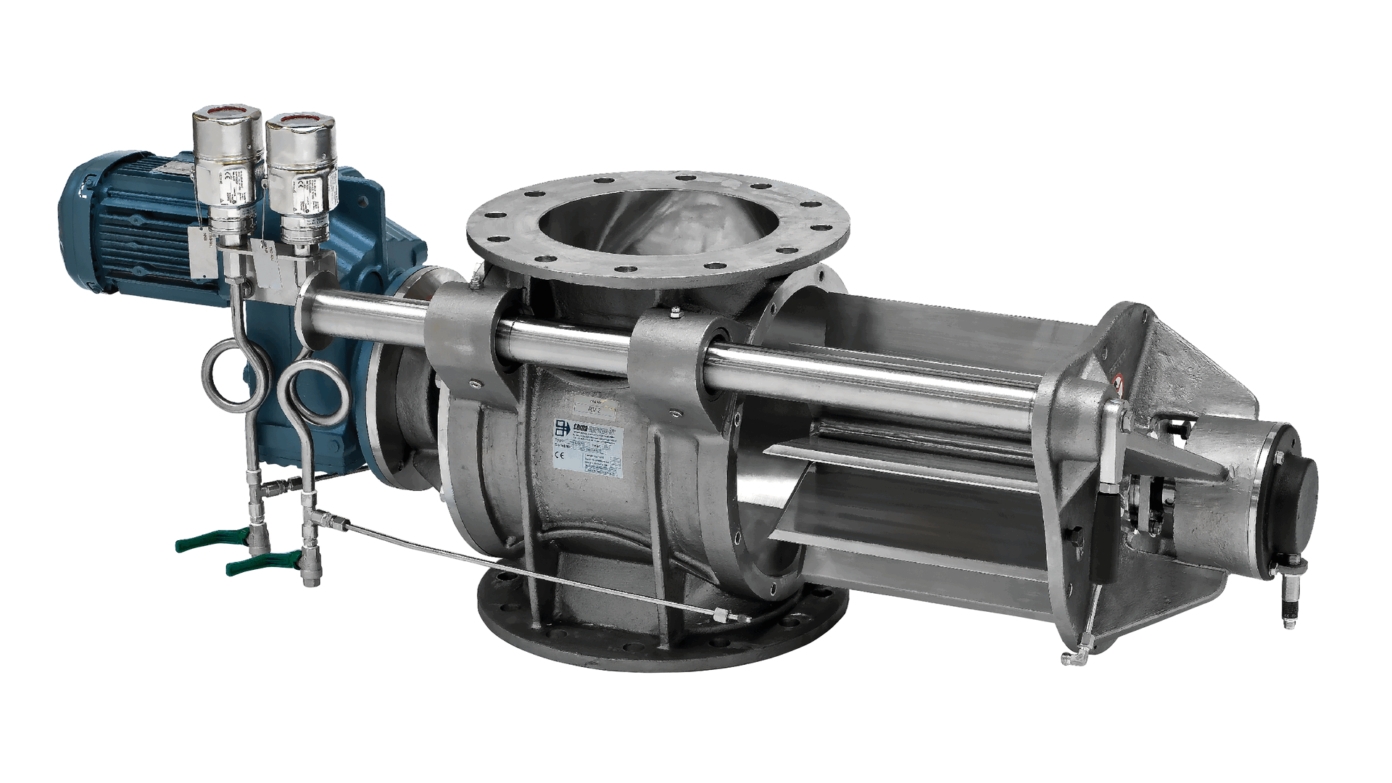

Rotating valves, often referred to as rotary airlocks, rotary feeders, and countless other variations, are used in bulk powder processing plants to regulate the flow of powder into and out of numerous crucial areas. Rotating valves are important for safety in addition to managing the flow of powder since they frequently serve as a flame barrier and process isolator in the case of a risky dust explosion.

Hence, here’s a comprehensive guide on how rotary airlock works, is there any difference between the rotary valve and rotary airlock & so on; you should know about rotary airlock feeders. Let’s read out to know more!

What is a Rotary Airlock Feeder/Valve?

As we know, rotary feeders and rotary valves are other terms for Rotary Airlock Valves. This device is suitable for both vacuum and pressure pneumatic conveying systems. These valves’ primary job is to act as a lock that stops air leakage, but they also serve as an important product that handles a variety of other functions. In other words, these rotary feeders are critical components of a conveying system’s efficiency. It is crucial to note that not all rotary valves are necessarily rotary airlock valves, but that all rotary airlocks are functionally air valves.

How Does a Rotary Airlock Work?

Rotary airlocks displace bulk solids from one vessel or atmosphere to another, while minimizing the loss of air pressure between them. In pneumatic conveying systems, rotary airlocks are used to charge bulk solids into the system or to remove them from collection devices (e.g. cyclone or dust collector) at the end of a system. Pneumatic systems use high-pressure fans or blowers to impart velocity to air thru a defined circuit of piping, carrying the bulk solids with it thru the system.

Furthermore, rotary valves are commonly referred to as “rotary airlock feeders” when used as an airlock and feeder to avoid air loss while displacing bulk solids, such as when transferring goods from a mass storage bin into or out of a pneumatic circuit. To minimize air loss in pneumatic circuits while maintaining airtightness, rotary airlock feeders are produced with precise tolerances. A rotary valve that serves as both an airlock and a feeder is similar to a revolving door in that it allows the material to pass through while maintaining air pressure within the structure.

Features of Rotary Airlock/Rotary Valves

Here are the following features of rotary airlock/rotary valve; take a look:

- There are options for blowing through and dropping through.

- It is offered with useful application tips.

- It regulated the flow rate of products

- This product works well with powdery and granular materials.

- It is made of cast iron for better air locking and accuracy.

- It serves as an isolator of the process.

What are the Best Rotary Airlock Models?

There are different sorts of airlock models available for varied bulk solids and applications. Stream channel, storage, pneumatic transportation, transit, and typhoon applications all require various types of airlock valves. The type of mass strong (dampness, roughness, toughness, pressure, flexibility, and evaluation) is also important in selecting the proper type of airlock exhibit. Rotary feeders were used to handling the products.

Things to Consider Before Purchasing Rotary Airlock Feeders:

There are several key factors to consider when selecting rotary airlock valves and rotary airlock feeders for your pneumatic conveying systems and dry bulk material handling systems: Keep this in mind!

- Processing method for bulk materials

- Type of application

- Optimum temperature

- The necessary degree of abrasion resistance

- Material thickness and moisture content

Conclusion:

Since rotary valves/rotary airlock feeders are important safety and efficiency mechanisms, selecting a high-quality rotary valve that fits your system is crucial. Furthermore, it can be challenging to decide which path to take given the range of customizations available in terms of type, size, material, function, and more.

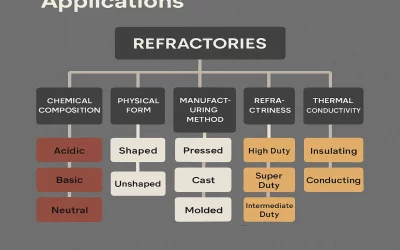

To help you select the best rotary valve/rotary airlock feeder for your powder processing plant, Ganeshas is one that pop-ups in mind first. As the leading manufacturer & supplier of refractory & mechanical materials, Ganesha’s are committed to serving clients with certified, quality-approved products. Get in touch with our team to get the best refractory & mechanical materials.