The glass industry is built on precision, durability, and efficiency. At the heart of this intricate process lies the use of refractories for glass industry applications. These heat-resistant materials are indispensable for constructing and maintaining glass furnaces, ensuring they can withstand extreme temperatures and chemical interactions.

But what makes these materials so vital, and how do they shape the future of glass production? Let’s explore.

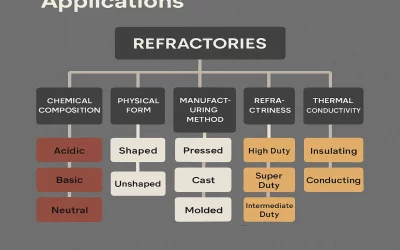

What Are Refractories and Why Are They Important?

Refractories are specialized materials engineered to endure high temperatures, resist chemical corrosion, and maintain structural integrity under extreme conditions. In glass manufacturing, their role is critical—they form the linings of furnaces where raw materials are melted into glass. Without glass refractories, furnaces’ operational efficiency, product quality, and longevity would be severely compromised.

The choice of refractory material directly impacts the performance of the furnace. High-quality refractories reduce energy consumption and minimize downtime caused by repairs or replacements. This makes them an essential investment for any glass manufacturer aiming for sustainability and profitability.

Types of Refractories Used in the Glass Industry

Fused Cast Refractories

Among the most widely used materials in glass furnaces are **fused cast refractories**. These are created by melting raw materials and casting them into molds, resulting in products with exceptional resistance to thermal shock, corrosion, and wear. Their low thermal expansion and high refractoriness make them ideal for areas exposed to extreme heat fluctuations, such as furnace crowns and sidewalls.

Alumina-Silica Refractories

These refractories are known for their excellent thermal stability and resistance to chemical attack from molten glass. They are commonly used in zones where durability is paramount.

Insulation Bricks

Lightweight yet robust, insulation bricks play a crucial role in reducing heat loss within furnaces. By improving thermal efficiency, they help manufacturers save energy while maintaining optimal furnace performance.

Other Specialized Materials

In addition to these, materials like zirconia-based refractories and magnesia bricks are used in specific furnace zones requiring enhanced resistance to alkalis or molten glass corrosion.

Applications of Refractories in Glass Furnaces

The application of glass furnace refractory materials spans multiple areas:

- Melting Tanks: Refractories here must withstand prolonged exposure to molten glass while maintaining chemical stability.

- Regenerators: These sections require materials like fused mullite that offer high creep resistance and thermal stability.

- Forehearths and Distributors: These areas demand refractories with excellent thermal shock resistance to ensure consistent temperature control during glass shaping.

- Boiler Bed Material: Certain refractories also serve as boiler bed material, enhancing combustion efficiency within auxiliary systems.

Each application demands tailored solutions to meet specific operational challenges, from resisting chemical corrosion to maintaining structural integrity under mechanical stress.

Ganeshas and Innovation

When discussing advancements in refractory solutions, it’s impossible not to acknowledge brands that push the boundaries of innovation. Ganeshas has been instrumental in delivering cutting-edge refractory solutions tailored to the unique demands of the glass industry. We focus on quality and sustainability to help manufacturers handle changing market needs without sacrificing performance.

The Future of Refractories in Glass Manufacturing

The road ahead for the glass industry is paved with opportunities—and challenges. As manufacturers aim for carbon neutrality and greater energy efficiency, advancements in refractory technology will play a pivotal role. Emerging innovations include.

- Enhanced formulations for fused cast refractories offer even greater durability.

- Lightweight yet robust insulation bricks that further reduce energy consumption.

- Sustainable practices such as recycling used refractories into new applications.

These developments not only promise cost savings but also align with global efforts toward sustainability.

Final Thoughts

Refractories are more than just materials; they are enablers of progress in the glass industry. From ensuring furnace longevity to improving energy efficiency, their impact is profound. As technology evolves, so too will the capabilities of these essential components.

For manufacturers aiming to stay ahead in today’s competitive market, investing in our high-quality refractory solutions is a smart move and a must. At Ganeshas, we believe continuous innovation and sustainable practices go hand in hand. Together, they are shaping the future of glass manufacturing, and we’re here to lead the way.

Refractories for the glass industry keep things running smoothly and improve performance. Choosing the right solutions helps manufacturers work smarter and achieve better results.