Your furnace just failed. Again. The maintenance team is scrambling, production is halted, and you’re staring at a six-figure repair bill. Sound familiar? You’re not alone – unplanned refractory failures can cost plants more than $1 million per day in lost production, and refractory failure is a major contributor to boiler shut-downs and the primary cause of boiler inefficiency.

Choosing the wrong different types of fire bricks doesn’t just impact your budget – it destroys your operational efficiency. But when you understand how to match refractory fire bricks to your specific applications, you’ll slash maintenance costs and extend equipment life significantly. That’s why it’s critical to know where to buy refractory fire bricks that match your plant’s needs.

Key Insights

- Refractory brick types selection can reduce your annual maintenance costs by 40-60%

- Understanding different types of fire bricks prevents costly furnace failures and unplanned shutdowns

- Fire brick types vary dramatically in performance – choosing wrong can cost you $50,000+ in repairs

- Strategic refractory fire bricks selection extends equipment life by 3-5 years on average

- Proper refractory design and installation can save 5-7% of fuel costs annually (Insulation Outlook, 2017)

- The global refractories market reached $35.98 billion in 2024, projected to grow at 6.0% CAGR through 2032

Why Your Current Brick Selection Might Be Costing You Thousands

Most facility managers select fire brick types based on initial cost alone. This approach backfires spectacularly. Consider this: a steel plant in Ohio switched from standard fireclay to high-alumina bricks and reduced their annual refractory replacement costs from $180,000 to $75,000 – a 58% reduction.

Your refractory selection directly impacts:

- Energy consumption (wrong bricks can increase fuel costs by 15-25%)

- Maintenance frequency (proper selection reduces repairs by 40-60%)

- Equipment lifespan (correct materials add 3-5 years of service life)

- Production uptime (quality bricks prevent 85% of thermal failures)

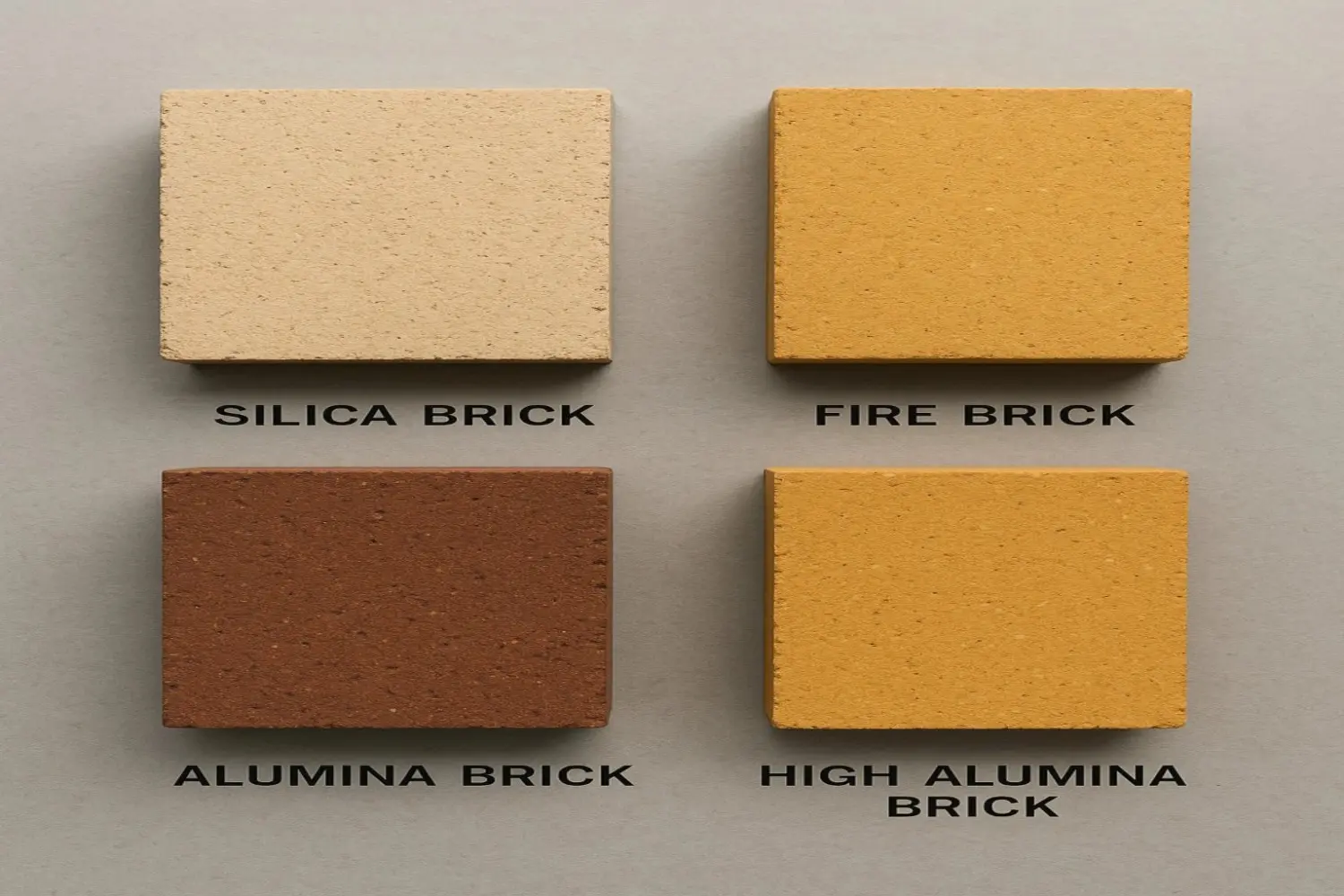

Silica-Based Refractory Brick Types: When Acid Resistance Matters Most

You’ll find silica bricks containing 94-98% silicon dioxide in your most demanding applications. These different types of fire bricks excel when you’re dealing with acidic environments and temperatures exceeding 1600°C.

When you should choose silica bricks:

- Glass manufacturing operations

- Steel production with acid slags

- Coke oven construction

- Applications requiring high thermal conductivity

Here’s what makes silica unique: these fire brick types expand predictably at 870°C, then stabilize. This behavior prevents the sudden dimensional changes that crack furnace walls and create expensive repairs.

Alumina Compositions: Your Go-To for Thermal Shock Resistance

Aluminum oxide content determines performance in these versatile refractory fire bricks. You’ll encounter three main categories:

Medium-Alumina Varieties (45-70% Al₂O₃)

These different types of fire bricks balance cost and performance perfectly for moderate-duty applications. You’ll see excellent results in cement kilns and general heating applications where thermal shock resistance matters more than extreme temperature capability.

High-Alumina Options (70-90% Al₂O₃)

When your operations involve rapid temperature changes, these fire brick types deliver superior performance. They handle thermal cycling that would destroy standard clay bricks within months.

Ultra-High Alumina Grades (90-95% Al₂O₃)

These premium refractory fire bricks represent the ultimate in thermal shock resistance and chemical stability. Companies like Ganeshas Refactory manufacture specialized ultra-high alumina compositions that meet the most demanding industrial requirements.

Magnesia-Based Solutions: Dominating Alkaline Environments

Your steel production and non-ferrous metal operations demand different types of refractory bricks that thrive in basic conditions. Magnesia bricks, containing 88-96% magnesium oxide, excel where alkaline slags and high temperatures converge.

You’ll achieve optimal results when:

- Operating in basic (alkaline) environments

- Processing temperatures exceed 1700°C

- Dealing with basic slags in steelmaking

- Managing copper and nickel refining operations

Critical warning: Never use magnesia fire brick types in acidic conditions. The chemical incompatibility will cause rapid deterioration and costly failures.

Thermal Performance Categories That Impact Your Bottom Line

High-Conductivity Refractory Brick Types for Energy Recovery

Silicon carbide and nitride-bonded different types of fire bricks conduct heat 12-18 times more effectively than standard materials. When you’re focused on energy recovery and heat exchange efficiency, these materials deliver measurable fuel savings.

Real-world application: A glass manufacturer installed high-conductivity recuperator bricks and reduced natural gas consumption by 22%, saving $180,000 annually in fuel costs.

Insulating Varieties for Energy Conservation

Lightweight fire brick types with 50-85% porosity create thermal barriers that slash energy consumption. You’ll reduce heat loss dramatically while maintaining structural integrity.

Quick calculation: Replacing dense backup insulation with lightweight insulating refractory fire bricks typically reduces fuel consumption by 15-30%, depending on your application.

Specialty Different Types of Refractory Bricks for Unique Challenges

Carbon and Graphite Solutions

Your aluminum smelting and foundry operations benefit from carbon-based fire brick types that resist thermal shock and remain chemically inert. These materials handle direct metal contact without degradation.

Chrome-Magnesia Composites

When you need the ultimate combination of thermal shock resistance and slag resistance, these hybrid refractory fire bricks deliver unmatched performance in rotary kilns and copper processing facilities.

Smart Selection Criteria

When matching materials to your operations, remember that Fire Brick vs Common Bricks is not just about temperature resistance—it’s about choosing materials that align with your chemical environment, thermal cycles, and installation practices.

Temperature Requirements Drive Everything

Different types of refractory bricks have specific thermal limits:

- Standard clay: up to 1350°C

- High-alumina: up to 1750°C

- Silicon carbide: beyond 2100°C

Action step: Document your peak operating temperatures and add a 100-200°C safety margin when selecting materials.

Chemical Environment Assessment

Your operating chemistry determines material compatibility:

- Acidic conditions: Choose silica-based fire brick types

- Basic environments: Select magnesia or chrome-magnesia options

- Neutral atmospheres: Alumina-based materials offer versatility

Thermal Cycling Considerations

Count your heating and cooling cycles per year. If you exceed 50 cycles annually, invest in high-alumina or silicon carbide refractory fire bricks for superior thermal shock resistance.

Finding Reliable Refractory Fire Bricks Suppliers

Partner with established manufacturers who provide:

- Technical support throughout installation

- Performance guarantees

- Comprehensive material testing

- Application-specific recommendations

Ganeshas Refactory offers complete technical expertise and a proven track record across diverse industrial applications, ensuring you receive optimal material selection and ongoing support.

Maximize Your Refractory Investment Today

Understanding different types of refractory bricks empowers you to make informed decisions that dramatically impact your operational success. From basic fireclay options to advanced composite materials, proper selection reduces costs, extends equipment life, and ensures reliable performance.

Ready to optimize your refractory selection? Start by evaluating your current materials against industry best practices and calculating potential savings from upgraded refractory fire bricks.