When the industry faces heat , it relies on Customised Refractory Solutions to keep operations running safely and efficiently. Whether it’s steel, glass, cement, or petrochemical plants, these fire-resistant materials form the backbone of high-temperature performance. The durability and safety of all these industries largely depend on Refractory solutions.

But here’s the exciting part! Refractories are no longer a one-size-fits-all industry. Modern manufacturing demands precision, durability, and energy efficiency, which is where Tailored Refractory Products come into play. Let’s explore the benefits of Custom Refractory Solutions and understand how they ensure long-term performance and plant efficiency.

Key Takeaways

- When your process reaches 1500 °C or more, standard insulation won’t cut it. That’s when Customised Refractory Solutions steps in!

- The global refractories market was valued at around USD 34.3 billion in 2024 and is projected to grow to USD 42.4 billion by 2029, at a CAGR of ~4.4 %.

- Within those numbers, application-specific or high-performance refractories are one of the fastest-growing segments.

What are Custom Refractory Solutions?

Custom refractory solutions are engineered high-temperature insulation materials designed specifically for a process, equipment, or industry. Unlike standard refractory materials, Application-Specific Refractories are built after studying factors like:

- Operating Temperature

- Thermal Shock Resistance

- Chemical Corrosion Environment

- Mechanical Load and wear conditions

In short, they’re not just fire-resistant industrial materials, they’re precision-built protection shields that extend the life and performance of furnaces, kilns, and reactors.

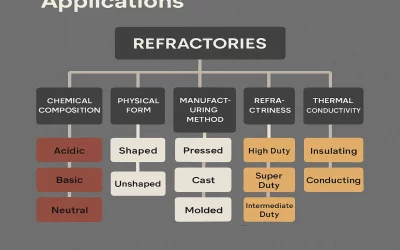

What are the Types of Refractory Materials in the Industry?

The best refractory materials manufacturer will offer a wide range of customizable options based on your industry’s demands. Here’s a quick look at common refractory classifications used to build tailored systems:

| Type | Description | Applications |

| Fired refractory products | Pre-fired for strength and uniformity | Furnaces, kilns, boilers |

| Castable Refractory | Poured into Molds for an exact fit | Complex furnace shapes |

| High alumina refractories | Excellent for heat-intensive processes | Steel and glass industries |

| Magnesia-based refractories | Superior resistance to basic slags | Metallurgy and cement |

| Corrosion-resistant refractories | Designed to resist chemical wear | Petrochemical reactors |

| Thermal shock refractories | Resist cracking under temperature shifts | Kilns, glass tanks, incinerators |

Benefits of Custom Refractory Solutions

Tailored Refractory Solutions provides numerous benefits, such as:

- Enhanced Energy Efficiency

- Longer Service Life

- Lower Maintenance Cost

- Improved Product Quality

- Optimised Performance

- Higher Safety & Reliability

How Industries Use Tailored Refractory Systems?

Let’s understand how these custom solutions can help the industries.

Silica refractory solutions: Used in oxidizing or silica-rich zones, often in the upper furnace sections or glass zones.

Alumina refractories / high alumina refractories: Widely used in steel and glass sectors, for temperatures 1200–1800 °C, providing stability and resistance.

Magnesia-based refractories: Ideal in basic slag conditions (steel, cement) for resistance to aggressive slags.

Corrosion-resistant refractories: Used in petrochemical furnaces or chemical reactors, where vapours are acidic or alkaline.

Thermal shock refractories: Used near cooling ends, burners, or cycling zones to withstand rapid temperature changes.

Fired refractory products: Pre-burnt bricks, shapes, etc., for structural strength.

Castable Refractory/monolithic products: Ideal for complex shapes, repairs, or sections where shaped bricks are impractical.

Why are Industries Switching to Tailored Refractory Products?

According to industry reports, refractories account for nearly 2-3% of total steel production cost, yet they directly influence over 40% of operational efficiency. That’s why more companies are now investing in tailored refractory systems to optimize performance and reduce downtime. Refractory Material manufacturers provide custom solutions to help with:

Thermal optimization: Reduces heat loss, saving 10–15% in energy costs

Longer service life: Decreases replacement frequency, lowering maintenance cost

Enhanced corrosion resistance: Improves durability in steel and glass furnaces

Precision design: Ensures exact fit for complex geometries

Operational safety: Kiln and furnace refractory materials minimize furnace failure risks

How to Select the Right Refractory Solution for Your Industry?

Want a refractory solution for your industry but don’t know how to choose one? Let us explain in detail:

Access Operating Conditions: Identify your process temperature, chemical atmosphere, thermal insulation solutions, and mechanical load.

Map Critical Zones: Locate furnace or kiln areas exposed to the highest heat, wear, or corrosion.

Match Material Type: Match material type, for example,

Magnesia-based refractories for basic slags (steel, cement).

High alumina refractories for high-temperature strength.

Silica refractory solutions for oxidizing zones.

Select Product form: Choose fired refractory products for durability or Castable Refractory for complex geometries and easy installation.

Consult Experts & Simulate Test: Partner with a trusted refractory materials manufacturer like Ganesha’s Refractories to get application-specific design and testing support.

Conclusion

In 2025 and beyond, you’ll see that Customised Refractory Solutions for the steel industry or any other are no longer considered luxury upgrades. They are becoming an important tool in maximizing energy efficiency, reducing emissions, improving uptime, and safeguarding high-temperature operations.

With the global demand for refractories scaling into tens of billions of dollars annually, the segment for tailored, application-specific refractories is rising faster than ever. From Castable Refractory mixes High Alumina Refractories, the future lies in Tailored high-temperature insulation products for industries, and with this, industries will no longer settle for standard but will build smarter, last longer, and perform better.

FAQs

What are Custom Refractory Solutions?

Custom Refractory Solutions are precision-engineered refractory systems designed specifically for your process or equipment, maximizing heat resistance, energy efficiency, and lifespan.

How do Tailored Refractory Products Benefit my Industry?

These products are specifically designed for your needs to enhance productivity, reduce maintenance, and improve thermal management, leading to lower operational costs.

Which Industries Need Customized Refractories Most?

Steel, glass, cement, and petrochemical industries rely heavily on custom refractory systems due to their extreme heat and corrosion environments.

How do I Select the Right Refractory Solution for my Industry?

Use a data-driven, zone-wise selection method with modelling, prototyping, and lifecycle monitoring. Partner with a reliable refractory materials manufacturer that understands refractory classification, customization, and support.