If you’re someone who follows the latest trends in construction and engineering, you’ve probably heard of insulating fire bricks. But what exactly are they, and why are they considered to be the next big thing in the refractory industry? To know the answer to your questions, read out the following article

What are Insulating Fire Bricks?

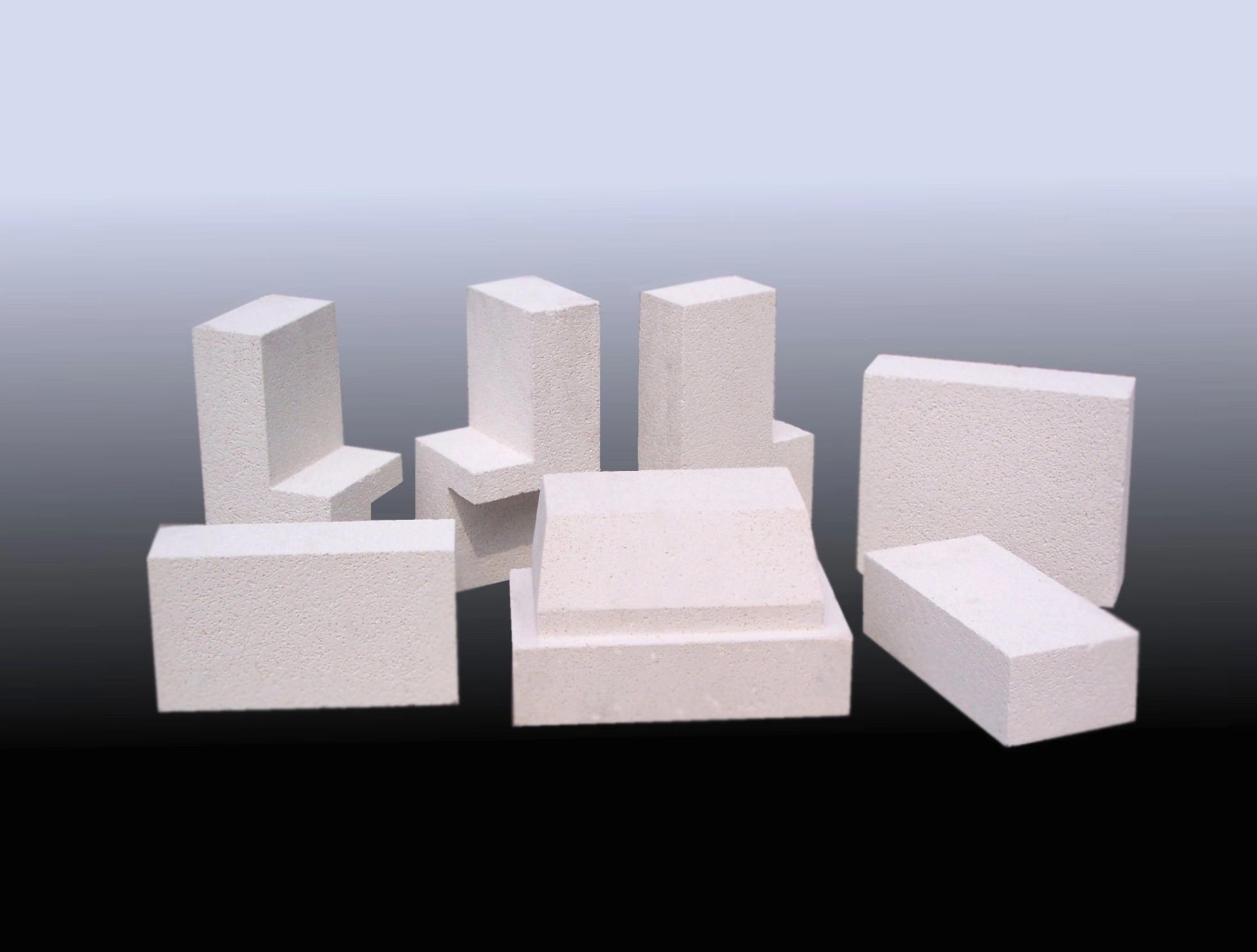

Insulating fire bricks is one type of soft brick that is comprised of refractory ceramic materials, a blend of alumina and silica sand, such materials can withstand high temperature and even has low thermal conductivity. Insulating fire bricks are ideal for forming creative shapes and custom cavities. In addition, insulating fire bricks is an outstanding insulator that never steps back to reflect heat well. Insulating fire bricks are quite light in weight and can easily be cut by hand tools like a chisel, drill, saw and so on

Moreover, there are the most demanded types of insulating fire bricks available in the market like high alumina insulation bricks, lightweight fireclay insulation bricks, mullite insulation bricks, alumina bubble bricks and the list goes on.

What is the Importance of Insulating Fire Brick?

Insulating fire bricks can act as insulation by handling high temperatures, such bricks are used to line furnaces, fireboxes, fireplaces, kilns, etc. In order to increase efficiency, these bricks can also withstand temperatures of up to 3200 degrees Fahrenheit while still conducting low heat. To help you know more benefits of insulating fire bricks, have a look!

Great Insulating Value: By improving efficiency and lowering operating costs, insulating fire bricks with their high insulation value and light weight enables thinner furnace walls.

High Compressive Strength: Because insulating fire bricks are compatible with dense fire bricks and strengthen the process as a whole, self-supporting structures are possible at high temperatures.

Reduce Heat Storage: In equipment that is operated in cycles, low heat storage and dense bricks reduce fuel costs and speed up the heating process.

Precision Dimension: Insulating fire bricks are machined to exact measurements, resulting in a stronger and tighter lining.

Extreme Purity: Insulating fire bricks have a low-impurity content, such as iron, which helps them perform better in refractory applications.

Insulating Fire Bricks vs Fire Bricks

You are not the only person who mistakenly believed that insulation fire bricks and fire bricks are interchangeable. However, there is a significant distinction between fire bricks and insulating fire bricks; let’s take a quick look.

Insulating Fire Bricks

– Insulating fire bricks, also known as soft bricks, are lightweight.

– The insulating fire brick has a heat conductivity of 0.2-0.4 (average temperature 350±25℃)w/m.k.

– Insulating fire bricks have a refractoriness of less than 1400 degrees Celsius.

– As Insulating fire brick is lightweight insulation material, its density is between 0.8-1.0g/cm3.

– Insulating fire bricks are ideally used for insulating furnaces, ovens, kilns and so on.

Fire Bricks

– Fire bricks also known as hard bricks are heavy and dense.

– The heat conductivity of refractory fire bricks is above 1.0(average temperature 350±25℃)w/m.k.

– The refractoriness of fire bricks is above 1400 degrees Celsius.

– The density of refractory fire bricks is above 2.0g/m3.

– Fire bricks are suitable for industrial furnaces, boilers and other high-temperature areas.

How to Find the Best Insulation Bricks?

Whether you’re searching for standard-quality insulating fire bricks or refractory fire bricks, your search ends here with Ganeshas Refractories. Ganshas Refractories is one of the top refractory manufacturers in India, who have years of experience in providing refractory materials as well as mechanical products. So without further ado speak to our team right away.