Every industrial furnace, kiln, and high-temperature chamber relies on a fundamental component that often goes unrecognized despite its critical importance: the fire brick. What is the purpose of fire bricks?

These specialized refractory materials form the essential foundation of thermal management systems across industries, enabling operations that would otherwise be impossible under extreme heat conditions.

Engineered to withstand temperatures that would compromise standard construction materials, fire bricks maintain their structural integrity while protecting surrounding equipment and personnel.

The purpose of fire bricks is more than just resisting extreme heat. They represent the culmination of centuries of material science evolution, designed to protect structures, enhance energy efficiency, and enable processes that would otherwise be impossible under extreme thermal conditions.

What Exactly Are Fire Bricks?

Before delving deeper into their applications, let’s establish a clear understanding of what is firebrick. Fire bricks are specialized ceramic blocks manufactured primarily from refractory clay materials with high alumina and silica content. What sets them apart from standard construction bricks is their exceptional ability to:

- Withstand temperatures exceeding 1500°C (2700°F) without melting or degrading

- Resist thermal shock (rapid temperature changes)

- Maintain dimensional stability even when exposed to intense heat

- Provide excellent thermal insulation properties

Fire bricks are typically denser and heavier than regular construction bricks, with a distinctive pale yellow or off-white appearance. Their composition is carefully engineered to maximize heat resistance while providing the necessary structural strength for their intended applications.

The Core Functions

The purpose of fire bricks can be broken down into several critical functions that make them indispensable in numerous applications:

1. Thermal Insulation and Heat Containment

The primary purpose of fire bricks is to insulate against heat. These specialized bricks create barriers that:

- Prevent heat transfer between compartments

- Maintain consistent temperatures within furnaces and kilns

- Protect surrounding structures from heat damage

- Improve energy efficiency by reducing heat loss

2. Structural Integrity Under Extreme Conditions

Unlike standard building materials that would quickly degrade under intense heat, fire bricks maintain their structural integrity even when subjected to temperatures that would melt metals. This makes them essential for.

- Lining industrial furnaces and kilns

- Creating high-temperature reaction chambers

- Building structures that must withstand direct flame contact

- Constructing heat-processing equipment with long operational lifespans

3. Chemical Resistance

We at Ganeshas have engineered our fire bricks to offer exceptional resistance to chemical reactions that commonly occur in high-temperature environments. Our advanced formulations protect against.

- Slag penetration in metallurgical applications

- Chemical erosion from process materials

- Reactions with alkaline or acidic compounds

- Degradation from combustion byproducts

According to a study published in Ceramics International on ScienceDirect, high-alumina refractory bricks exhibit greater resistance to alkali attack in industrial environments, such as rotary kilns. The research highlights that bricks with higher alumina content develop a dense microstructure and stable phases like mullite and corundum, which significantly slow down the penetration of alkali vapors and minimize degradation at the refractory surface

Where Fire Bricks Prove Their Worth

The versatility and heat-resistant properties of fire bricks make them indispensable across numerous industries and applications.

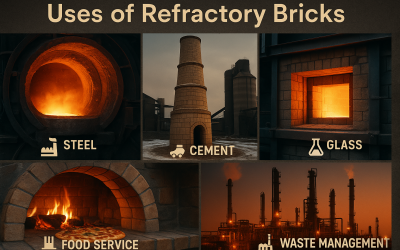

Industrial Manufacturing

In heavy industrial settings, fire bricks form the critical lining of.

- Blast furnaces for steel production

- Glass melting tanks

- Cement kilns

- Petroleum refining equipment

- Chemical processing vessels

These applications expose materials to some of the most extreme conditions imaginable, where temperatures can reach well above 1000°C for extended periods.

Energy Production

- Power plant boiler linings

- Waste incineration facilities

- Coal gasification chambers

- Nuclear plant thermal management

In these applications, the purpose of fire bricks extends beyond heat containment to include radiation shielding and protection against highly corrosive environments.

Commercial Cooking and Food Production

- Commercial pizza ovens

- Bakery kilns

- Smokehouses

- Wood-fired restaurant kitchens

Here, fire bricks not only contain heat but also help create the specific cooking environments that give many foods their distinctive characteristics through even heat distribution.

Residential Applications

Even in residential settings, what is firebrick becomes evident.

- Home fireplaces and wood stoves

- Outdoor brick ovens

- BBQ pits and smokers

- Masonry heaters

Types of Fire Bricks

Understanding what is the purpose of fire bricks requires knowledge of the different types available, each designed for specific applications:

Dense Fire Bricks

- Composition: High alumina content (30-99%)

- Temperature resistance: Up to 1800°C

- Applications: Direct flame contact, structural support

- Characteristics: High density, excellent load-bearing capacity

Insulating Fire Bricks

- Composition: Refractory clay with added porosity

- Temperature resistance: 900-1600°C depending on grade

- Applications: Thermal insulation, energy efficiency

- Characteristics: Lightweight, lower thermal conductivity

Special-Purpose Fire Bricks

- Composition: Varies based on application (silica, magnesia, chromite)

- Temperature resistance: Tailored to specific environments

- Applications: Specialized industrial processes with unique requirements

- Characteristics: Enhanced resistance to specific chemicals or conditions

Selecting the Right Fire Bricks: A Business Perspective

For businesses investing in high-temperature equipment or facilities, selecting the appropriate fire bricks represents a critical decision that impacts:

- Operational efficiency and energy costs

- Maintenance schedules and downtime

- Equipment lifespan and reliability

- Safety standards and compliance

Working with established industry leaders ensures access to materials that meet stringent quality standards and performance requirements. The initial investment in premium fire bricks typically yields significant returns through extended service life and improved operational efficiency.

Conclusion

As we’ve explored throughout this article, the purpose of fire bricks extends far beyond simple heat resistance. These specialized materials represent a critical enabling technology for countless industrial processes and even residential uses. Their ability to withstand extreme temperatures while maintaining structural integrity makes them irreplaceable components in the modern world.

Providing durable, high performance refractories is one of Ganeshas’ trademarks. Our team of specialists works closely with clients to identify the optimal fire brick formulations for their specific applications, ensuring maximum return on investment through extended service life and improved operational efficiency.